🌟 Editor's Note

Welcome to another exciting week in the Vision AI ecosystem! We've got a packed newsletter full of insights, events, and inspiring stories from the heart of innovation.

🗓️ Tool Spotlight

NVIDIA releases Nemotron-VLM-Dataset-v2 :

Ubicept has announced the release of the Ubicept Toolkit, a physics-based imaging solution that enables both cutting-edge and conventional cameras (including standard CMOS sensors) to deliver high-quality, reliable visual data.

The Toolkit works with conventional cameras to improve perception in challenging conditions — such as low light, high dynamic range and motion — and also supports next-gen SPAD (single-photon) sensors for advanced imaging.

Ubicept says this approach produces more trustworthy data than typical AI-based video enhancement, making it valuable for autonomous systems in robotics, automotive, industrial sensing and more. The Toolkit will be available starting December 2025. [link]

🚀 Blog Spotlight

KPMG’s latest report on Vision AI’s impact

VisionAI is reshaping industrial manufacturing by merging AI, IoT, and computer vision to deliver faster, smarter, and more autonomous operations. As U.S. manufacturers face rising costs, VisionAI adoption is accelerating—driving a global computer vision market projected to grow from $24B in 2025 to $58B by 2030.

Companies using VisionAI report up to a 50% reduction in unplanned downtime and 97% defect-detection accuracy versus 70% manually.

Digital twin adoption is also rising, with the market expected to reach $99B by 2029. VisionAI now underpins fault detection, process automation, and real-time decision-making, enabling hyper-efficient, self-optimizing factories. [link]

🦄 Startup Spotlight

FloVision Solutions is a startup (founded in 2020) that builds AI-powered analytics systems for food production and processing — especially protein/meat processing — to reduce waste, improve yield, and optimize quality and staff performance.

Their products (like FloVision Nano and FloVision Pro) integrate sensors on conveyors and workstations; they scan and measure each item (weight, dimensions, quality, defects, etc.), detect defects or spec-mismatches.

All data flows into a centralized dashboard giving real-time yield, quality and staff-performance analytics. This helps food processors reduce waste, meet customer specs, and maximize profits while also improving operational sustainability.

In July 2025, FloVision raised a $8.7 M Series A funding round — led by Insight Partners — to scale globally, expand its engineering/AI/sales teams, and accelerate deployment across multiple continents. (link)

Yield Analysis using FloVision Nano

🔥 Paper to Factory

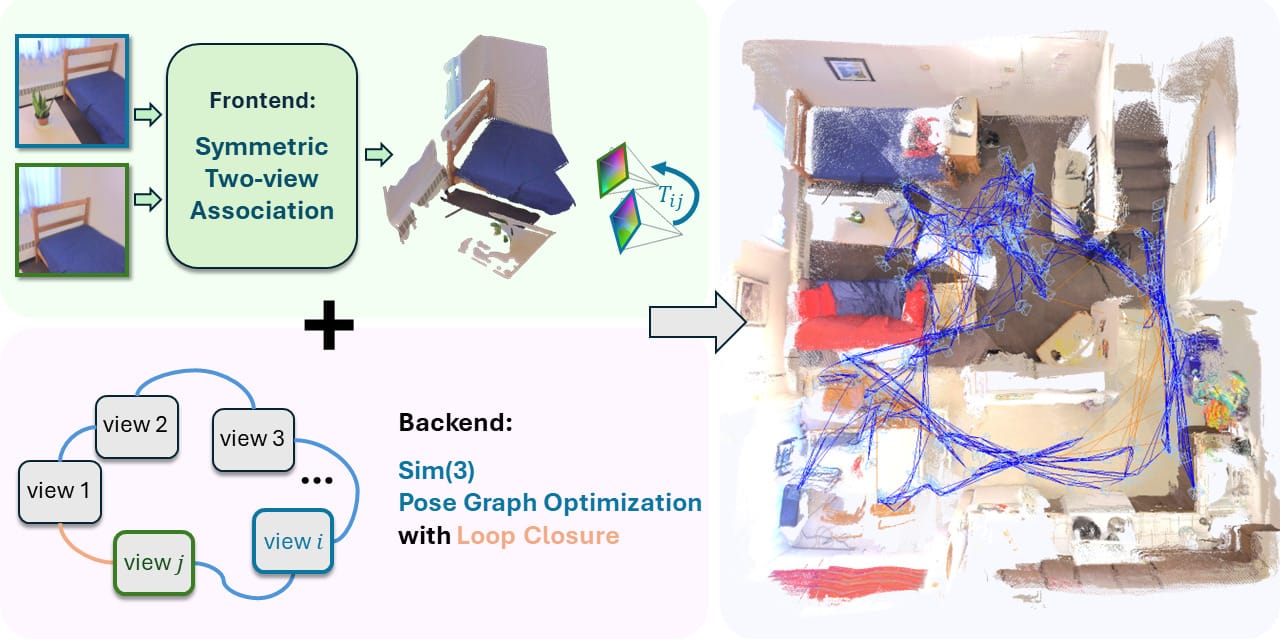

Ganlin Zhang and colleagues introduce ViSTA-SLAM, a real-time monocular visual SLAM system that works without knowing camera intrinsics — so it can use almost any RGB camera.

Its frontend uses a lightweight symmetric two-view association (STA) model that takes pairs of RGB images and jointly predicts the relative camera pose plus local point-maps.

The frontend is much smaller than comparable methods (only ~35% of their size), yet produces high-quality constraints for mapping.

The backend builds a Sim(3) pose-graph with loop closures and optimizes it using Levenberg–Marquardt to correct drift. Experiments show ViSTA-SLAM achieves superior camera tracking and dense 3D reconstruction quality compared to current state-of-the-art SLAM systems. (arXiv)

🏆 Community Spotlight:

The recent Labeller AI’s video highlights powerline inspection using latest in computer vision

Roboflow’s latest video highlights on a complete analysis of a basketball scenario using their latest tools

Till next time,